Description

● Optical Fiber Composite Low Voltage Electric Cable (OPLC)/Photoelectric Composite Cable:

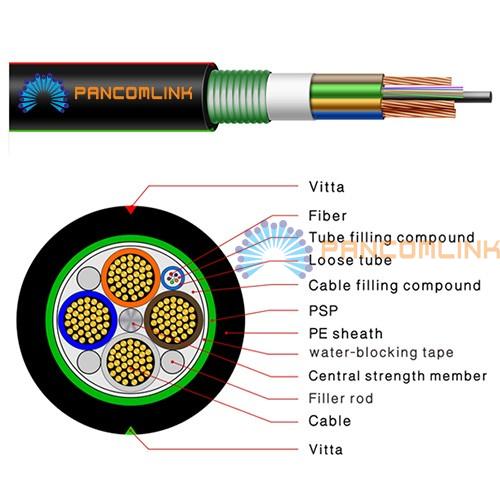

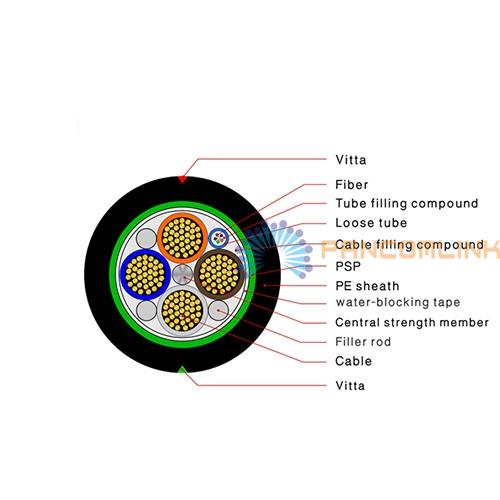

The structure of the photoelectric hybrid cable is to cover 250um optical fiber into the loose tube of the high modulus material. The core of the cable core is a FRP or metal core (some structures need to add a layer of PE cushion layer). The electric wire and the loose tube (and the filling rope) surround the center to strengthen the core to synthesize the compact and circular cable core. Double coated strip (PSP) longitudinal package after extruded polyethylene or low smoke halogen (LSZH) cable sheath.

● Features:

►Good flexibility and mechanical properties;

►Opto and electricity integrated, fully save pipeline resources;

►Electric and optical cable maintain relatively independent structure, easy to import, export and link when installation;

►Electricity lines, telephone lines, television lines, network lines, monitor lines and data lines are multi-one network, saves costs;

►Larger operating temperature range;

►Larger construction temperature range;

►Optical cable diameter and bending radius are small, in the next small space also can freely install compatible optical signal transmission and power transmission at the same time;

►Light cable tensile, impact, bending, flattening, torsion, winding and wear in compliance with YD/T901-2001 requirements.

● Application:

►Telecommunications network;

►Construction of communication base stations in villages, remote areas in cities and towns;

►Residential areas and buildings FTTH;

►Security monitoring project;

►Others occasion which information together with electric power at the same time.

·

● Technical Advantages:

►Perfect design for transmission lines, highly effect for electricity saving;

►Opto and electricity integrated, conveys electric energy and information at the same time, and keep monitoring wire lines;

►Optical fiber compounded in the wire, preventing fiber broken and split accidents by ground lightning;

►Preventing cable suffered corrosion, ruinning or fiber broken accidents caused by field strength;

►Additional load brings no hidden danger for original lines.

● Optical Characteristics:

|

|

G.652 |

G.655 |

50/125μm |

62.5/125μm |

|

|

Max attenuation |

@850nm |

|

|

3.5dB/km |

3.5dB/km |

|

@1300nm |

|

|

1.5dB/km |

1.5dB/km |

|

|

@1310nm |

0.45dB/km |

0.45dB/km |

|

|

|

|

@1550nm |

0.30dB/km |

0.30dB/km |

|

|

|

|

Typical attenuation |

@850 |

|

|

3.0dB/km |

3.0dB/km |

|

@1300 |

|

|

1.0dB/km |

1.0dB/km |

|

|

@1310nm |

0.40dB/km |

0.40dB/km |

|

|

|

|

@1550nm |

0.25dB/km |

0.25dB/km |

|

|

|

|

Mini bandwith |

@850 |

|

|

400MHZ·km |

160MHZ·km |

|

@1300 |

|

|

800MHZ·km |

500MHZ·km |

|

● Technical Parameters:

|

Item |

|

Technical Requirement |

Remark |

|

Allowable bending radius(mm) |

Dynamic |

30D |

|

|

Static state |

20D |

|

|

|

Allowable pull(N) |

Short-term |

3000 |

|

|

Long-term |

1500 |

|

|

|

Allowable press force |

Short-term |

3000 |

|

|

Long-term |

1000 |

|

|

|

Operating temperature range |

wire |

-15℃~+70℃ |

Meet GB5023-1997 |

|

Other materials other than |

-40℃~+70℃ |

|

|

|

Water resistance/waterproof performance |

Long term immersion in water without water seepage |

Except the conductor of the wire |

|

|

No leakage |

|||

|

Construction temperature range |

-20℃~+60℃ |

In addition to electric wire |

|

|

-0℃~+60℃ |

wire |

||

|

Weight |

374kg/km(RV-2*2.5mm) |

|

|

|

Mechanical properties |

The optical cable tensile, impact, bending, flattening, torsion, winding and wear in compliance with YD/T901-2001 requirements |

||

|

Applicable laying mode |

Suitable for pipe, channel, cable trench, aerial, buried and other installation |

||